Geosintetici

Tvrtka G.T. Trade d.o.o. posjeduje specifično iskustvo i profesionalan pristup u odabiru materijala za sve primjene. Naša uporaba modernih tehnologija u skladu je sa zahtjevima EU standarda. Predani smo stalnom usavršavanju, kao i sprječavanju onečišćenja okoliša. Oblikujemo okoliš u kojem živimo kako bismo što učinkovitije iskoristili krajolike, bez negativnih posljedica. S našim rješenjima i materijalima koje ugrađujemo u različite primjene činimo sve da ispunimo te zahtjeve.

Tvrtka je aktivno uključena u zaštitu okoliša kroz sanaciju odlagališta, zaštitu voda, zaštitu voda u cestogradnji te izgradnju željezničkih koridora i laguna. Sigurno zbrinjavanje otpada cilj je svake zajednice, kao i jedan od preduvjeta održivog razvoja. Nekontrolirano odlaganje otpada povećava opasnost od onečišćenja tla i vode. Primjena geosintetičkih materijala, koji olakšavaju gradnju zahvaljujući svojoj učinkovitosti i jednostavnosti, pomaže nam u zaštiti okoliša i njegovih resursa, a istovremeno čini odlaganje otpada sigurnijim.

Na odlagalištima se gotovo isključivo koriste HDPE geomembrane debljine veće ili jednake 2,0 mm. U zaštiti podzemnih voda, uglavnom se koriste HDPE geomembrane debljine 1,0 mm. U primjenama u tunelima, najčešće se postavljaju geomembrane s signalnim slojem. Strmiji nagibi mogu se prilagoditi ugradnjom geomembrana sa strukturiranim površinama. Iglom probušene geosintetičke glinene brtvene obloge s mehanički povezanim netkanim materijalima (300 g/m2) kao pokrovnim i nosećim geotekstilima posebno su prikladne za strmije padine jer obično postižu veće kutove trenja na sučelju u usporedbi s drugim geotekstilima.

Brtvljenje je neophodno za zaštitu okoliša i podzemnih voda te značajno doprinosi upotrebljivosti i vijeku trajanja građevina. Geomembrane različitih debljina, ovisno o namjeni, koriste se kao barijere za tekućine i plinove, uglavnom na odlagalištima, u izgradnji tunela i u hidrotehnici. Obično se koriste geomembrane proizvedene od različitih formulacija polietilena (npr. različitih gustoća). Debljine su općenito veće od 1,0 mm. Geomembrane postavljaju i zavaruju ovlašteni instalateri. U područjima s manjim opterećenjima, mogu se koristiti plastične folije debljine od 0,3 mm do 1,0 mm, što je primjenjivo za privremene pokrove i, na primjer, za primjene u jezercima. Geosintetičke glinene brtvene obloge koriste se u specifičnim područjima, pri čemu bentonit obavlja funkciju brtvljenja.

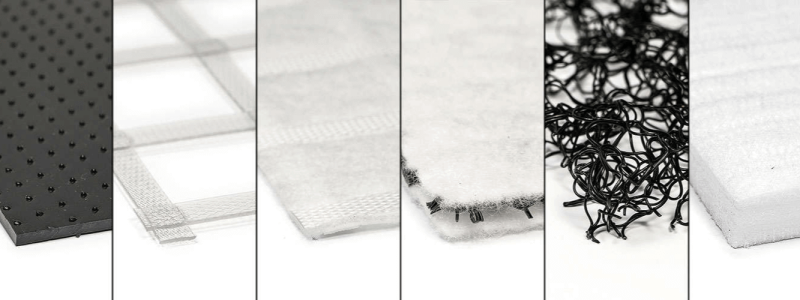

Proizvodi:

Kako bi se omogućila dugotrajna drenažna funkcionalnost perkolacijske slojeve, koriste se filtracijski geotekstili za prijenos smičnih naprezanja na perkolacijski sloj. Mehanički povezani netkani materijali (vidi filtraciju) posebno su prikladni za filtracijske funkcije. Nasumično zapetljane mrežaste matrice osobito su pogodne kao drenažni slojevi jer imaju stabilnu trodimenzionalnu statičku strukturu. Smična naprezanja mogu se prenijeti bez oštećenja, čime se održava dugoročna hidraulička učinkovitost.

Drenaža uključuje prikupljanje oborina, podzemnih voda i drugih tekućina ili plinova koji se moraju odvoditi. Drenažni sustavi se isporučuju kao pojedinačni elementi ili kompoziti koji se sastoje od najmanje jednog filtracijskog sloja i jednog perkolacijskog sloja. Perkolacijski sloj preuzima tekućinu i odvodi je uz minimalan gubitak tlaka. Površinski drenažni sustavi često se kombiniraju s brtvenim sustavima, primjerice na odlagalištima, te u aplikacijama za hidroizolaciju, poput podzemnih parkirališta ili tunela. Geosintetički drenažni sustavi zamjenjuju skupe mineralne drenažne slojeve.

Proizvod:

Mehanički povezani netkani materijali posebno su prikladni za ovu funkciju jer se vrlo dobro prilagođavaju nepravilnim podlogama, kao i mekim tlima, zahvaljujući svojoj visokoj sposobnosti izduženja. Ova sposobnost izduženja važna je kako bi se prilagodila penetraciji kamena. Vlakna se obavijaju oko kamena i sprječavaju oštećenje strukture netkanog materijala.

Geotekstili razdvajaju susjedne tipove tla ili nasipne materijale, sprječavajući njihovo međusobno miješanje. Koriste se u obliku izdržljivih, robusnih netkanih ili tkanih tkanina i/ili kompozita proizvedenih od sintetičkih sirovina koje mogu podnijeti visoka opterećenja. Uobičajene primjene uključuju cestogradnju i željezničku gradnju, hidrotehničke projekte te izgradnju jahaćih i sportskih terena. Odabir odgovarajućeg proizvoda ovisi o raspodjeli veličine zrna materijala temeljnog sloja i očekivanim operativnim opterećenjima.

Proizvod:

Debeli mehanički povezani netkani materijali pokazali su se vrlo dobrim zaštitnim slojevima. Primjerice, Secutex® PP netkani materijali s masom po jedinici površine većom od 800 g/m² koriste se kao jedini zaštitni sloj za geomembrane. Međutim, u područjima primjene gdje se javljaju manja opterećenja, koriste se mehanički povezani netkani materijali s masom po jedinici površine većom ili jednakom 300 g/m².

Geomembrane, obložene i neobložene strukture moraju biti zaštićene od mehaničkih oštećenja. Bez zaštitnih slojeva, došlo bi do oštećenja uzrokovanih oštrim nepravilnostima podloge ili materijala za nasipavanje. Netkani materijali i kompoziti koriste se kao zaštita od mehaničkih oštećenja. Kompoziti uključuju netkane materijale ojačane tkanim materijalima, dvostrano tkane materijale i kompozitne netkane materijale s mineralnim ispunama. Učinkovitost zaštite ovisi o debljini geosintetika, njihovoj masi po jedinici površine, kao i otpornosti na perforacije uzrokovane udarcima ili kompresijom. Netkani materijali i kompoziti koriste se u raznim primjenama, uključujući odlagališta i tunele, za zaštitu geomembrana. Takvi zaštitni elementi uspješno su ugrađeni i u izgradnji cjevovoda.

Proizvod:

Uglavnom se georešetke i tkani materijali koriste kao elementi za ojačanje. Elementi za ojačanje, kod kojih su ojačani dijelovi napravljeni od niti izrezanih filmova (npr. tkani materijali), podložniji su oštećenjima prilikom instalacije nego elementi za ojačanje napravljeni od polimernih rebara s čvrstim točkama presjeka. Osim toga, rastegnute georešetke imaju manja početna izduženja u usporedbi s tkanim materijalima, na primjer, i stoga odmah prenose sile bez produžetka tijekom gradnje.

Kada se koriste za svrhe ojačanja, geotekstili, georešetke i kompoziti postavljaju se ispod ili između slojeva tla kako bi preuzeli vlačne sile i time poboljšali mehanička svojstva. Prednost se daje njihovoj upotrebi u potpornoj konstrukciji temeljenoj na principu „ojačanog tla“ ili za stabilizaciju zemljanih nasipa na tlima s lošom nosivosti. U mnogim slučajevima ovo čini skupe konstruktivne mjere, zamjenu tla ili postavljanje dodatnog sloja tla nepotrebnim.

Proizvodi:

Mehanički povezani netkani materijali posebno su prikladni za ovu funkciju ako je debljina netkanog materijala barem 30 puta veća od odabrane veličine otvora. To je utvrđeno inspekcijama mehanički povezanih netkanih materijala koji su u upotrebi tijekom relativno dugih razdoblja. Debljina prilagođena veličini otvora omogućava dubinsku filtraciju i sprječava stvaranje filter kolača na sučelju između geotekstila i tla, što bi smanjilo propusnost vode. Time se dugoročno osigurava propusnost vode kod mehanički povezanih netkanih materijala prilagođenih tlu.

Geotekstilni filtracijski sloj zadržava krute čestice, dok tekućinama omogućuje gotovo slobodan prolazak okomito na filtracijsku ravninu. Razlikuje se između mehaničke čvrstoće (kapacitet zadržavanja čestica tla) i hidrauličke učinkovitosti filtra, s ciljem postizanja odvodnje vode uz minimalan gubitak tlaka.

Zahtjevi se također mogu ispuniti mineralnim filtrom, no geotekstilni filter slojevi pokazali su se kao najprikladnija i najekonomičnija alternativa.

Kao i kod mineralnih filter slojeva, debljina geotekstilnih filtera može utjecati na dugoročnu mehaničku i hidrauličku učinkovitost filtra. Filteri se uglavnom koriste u hidrotehničkim sustavima i sustavima odvodnje.

Proizvodi:

- Secutex®

- Terrafix®

Zbog svoje vrlo dobre fleksibilnosti, mehanički povezani netkani materijali posebno su prikladni jer omogućuju robusno rukovanje zahvaljujući optimalnom ponašanju pod naprezanjem/istezanjem te se dobro prilagođavaju podlozi. Osim toga, fleksibilni sustav se optimalno deformira prilikom udarca valova, apsorbirajući udarne sile. Trodimenzionalni iglom probušeni netkani materijali su također posebno otporni na abraziju.

U geotehnologiji i hidrotehnici, zemljani materijali se posebno “pakiraju” u fleksibilne cijevi, vreće i kontejnere. Ovdje geosintetici obavljaju funkcije razdvajanja, filtriranja, zaštite i/ili ojačanja, ovisno o vrsti primjene. Materijali koji se koriste uključuju netkane tkanine, tkane materijale, georešetke i kompozite.

Proizvod:

- Soft Rock® (Terrafix®)

Erozija padina može se vrlo učinkovito spriječiti upotrebom zapetljanih mrežastih struktura, osobito tijekom faze vegetacije, jer se tlo ispunjeno u trodimenzionalnu statičku strukturu nasumično zapetljane mreže sigurno drži na mjestu i postaje relativno otporno na ispiranje.

Trodimenzionalni geosintetici i kompoziti sprječavaju uklanjanje čestica tla uslijed djelovanja vode i vjetra. U prirodi biljke sa svojim korijenjem sprječavaju odnošenje tla. Prirodni proces formiranja slojeva vegetacije, koji često traje godinama, može se ubrzati i poboljšati uporabom prostirki za kontrolu erozije.

Proizvod:

Tvrtka G.T. Trade d.o.o. je generalni zastupnik njemačke tvrtke NAUE GmbH & Co. KG za područje Hrvatske i Bosne i Hercegovine. U proteklih 40 godina, tvrtka NAUE GmbH & Co. KG proširila je svoj asortiman proizvoda i područje njihove primjene, čime je osigurala prisutnost na najvažnijim svjetskim tržištima. Danas na području Hrvatske i Bosne i Hercegovine nudimo proizvode ove tvrtke, zajedno s idejnim i tehničkim rješenjima za gradilišta, uključujući sve geostatičke i geotehničke proračune.

G.T. Trade d.o.o. upravlja lancem opskrbe od odabira i nabave materijala do međunarodne logistike, isporuke i ugradnje. Mi smo jedan od najvećih uvoznika geosintetičkih materijala u Hrvatskoj.

Raspolažemo visokokvalitetnim materijalima koji su testirani od strane akreditiranih stručnih organizacija za certificiranje i kontrolu kvalitete, kao i provjerenim rješenjima temeljenim na iskustvu te sveobuhvatnom tehničkom podrškom za sve faze projekta – od prijedloga do isporuke materijala i ugradnje.

Glavne i izvedbene projekte izrađujemo u suradnji s našim projektnim uredom (BBG/ BAUBERATUNG GEOKUNSTSTOFFE).

BENTOFIX®

BENTOFIX® brtvena barijera

Iglom probušena ojačana geosintetička glinena obloga (GCL) s dva sloja geotekstila koja kapsuliraju sloj natrijevog bentonita za primjene brtvljenja.

BENTOFIX® X višekomponentna brtvena barijera

Iglom probušena GCL, gdje je tkana tkanina obložena poliolefinskom prevlakom niske propusnosti i nepropusnom za plinove kako bi se postigla trenutna barijera prije hidratacije.

Bentofix® je multifunkcionalan

Bentofix® je iznimno svestran proizvod na bazi gline. Nakon hidratacije, Bentofix® postaje učinkovita barijera protiv tekućina, para i plinova. S više od dva desetljeća uspješnih instalacija, raspon primjena Bentofix®-a praktički je neograničen.

- pokrovni slojevi za otpad i kontaminirano tlo

- podložne membrane za odlagališta

- brtve za plin i pare

- površinske obloge akumulacija

- sekundarna zaštita

- brane, kanali i vodeni tokovi

- obuzdavanje jalovine

- zaštita podzemnih voda

- upijajuće barijere

- vertikalne barijere

- hidroizolacija

- raznolike primjene za brtvljenje s različitim vrstama GCL-a i natrijevim bentonitom

- može smanjiti troškove izgradnje zamjenom zbijene gline

- robustni geotekstili kapsuliraju i sadrže bentonit

- izdržava diferencijalna slijeganja

- ujednačena čvrstoća ljuštenja osigurava višesmjernu smičnu čvrstoću

- Thermal Lock proces povećava unutarnju smičnu čvrstoću i kutove trenja na sučelju

- dostupni preklopi koji se sami brtve

- prednosti ugradnje s rolama širine 5 m

- brza i jednostavna ugradnja

- BBA certificirani sustavi hidroizolacije (Bentofix® BFG 5000 i X2 BFG 5300)

- ISO 9001 certificirano

- CE označeno

SECUTEX®

SECUTEX®

je iglom probušen netkani geotekstil od spajalnih vlakana, a neki proizvodi su dodatno kalandrirani, koriste se za separaciju, filtraciju, zaštitu i drenažu.

SECUTEX® JE MULTIFUNKCIONALAN

Geotekstili Secutex® koriste se u mnogim područjima građevinskog inženjerstva, uključujući hidrotehniku, inženjering odlagališta, cestogradnju i izgradnju tunela. Kao sloj za separaciju, Secutex® sprječava kontaminaciju između pojedinačnih i različitih granularnih slojeva. Time se strukturalni nasipi i osnovni slojevi održavaju netaknutima značajno dulje nego što bi to inače bilo moguće. Kada su prisutni fini slojevi tla uz drenažne slojeve na projektima izgradnje autocesta ili željeznica, Secutex® djeluje kao filter, sprječavajući ispiranje finih čestica tla i ugrožavanje drenažnih sposobnosti grubljih slojeva. Pomični sloj vode u problematičnim područjima olakšan je ravninskom propusnošću Secutex®-a. Netkani geotekstili Secutex® s visokom masom po jedinici površine također mogu zaštititi geomembrane ili cijevi od mehaničkih oštećenja. Ako je potrebno, u matricu Secutex®-a može se integrirati tkani geotekstil za raspodjelu dinamičkih opterećenja, čime se povećava njegova zaštitna sposobnost.

TERRAFIX®

TERRAFIX®

je jednostruki ili višeslojni, iglom probušen netkani materijal za primjene u separaciji, filtraciji, zaštiti i aplikacijama sa spremnicima pijeska.

TERRAFIX® JE MULTIFUNKCIONALAN

Terrafix® je svestran materijal koji se koristi za širok raspon funkcija, uključujući jednostruke ili višeslojne geotekstilne filtere, prostirke s balastom od pijeska, spremnike ili cijevi od pijeska te zaštitu od erozije. Netkani materijali i prostirke Terrafix® djeluju kao separatori i filteri u hidrotehničkim primjenama, poput izgradnje nasipa, sanacije i zaštite korita kanala te obalnih radova. Terrafix® cijevi izrađene od ovog materijala koriste se za zaštitu bazena u lukama; spremnici s pijeskom Terrafix® uspješno su korišteni za zaštitu obala i riječnih korita. Terrafix® ima visoku propusnost za vodu, zadržava tlo i omogućuje rast korijenja, tako da se strukture za zaštitu obala neprimjetno stapaju s prirodnim okolišem. Terrafix® pruža zaštitu od erozije za obloge, u plovnim putovima, oko stupova te uzdužne i poprečne hidrotehničke strukture.

CARBOFOL®

Carbofol® HDPE geomembrane proizvode se od visokokvalitetnih polietilenskih smola. Carbofol® se izrađuje u različitim debljinama i do širine od 7,50 m. Za primjene brtvljenja na padinama, Carbofol® se proizvodi s reljefnom strukturom.

- Pokrovni slojevi i bazna brtvljenja odlagališta

- Kanali, jezerca i rezervoari

- Tuneli i zgrade

- Rudarstvo

- Skladištenje, punjenje, rukovanje, proizvodnja, tretman i uporaba kontaminiranih tekućina

- Izvrsna kemijska otpornost zahvaljujući odabranim sirovinama

- Visoki kutovi trenja na sučelju zahvaljujući reljefnoj strukturiranoj površini

- Prednosti ugradnje s oblogama širine do 7,50 m

- Visok Melt Flow Index (MFI) omogućuje izvrsnu izvedbu zavarivanja

- Dostupno u skladu s GM-13 standardom te s BAM i DIBt odobrenjem

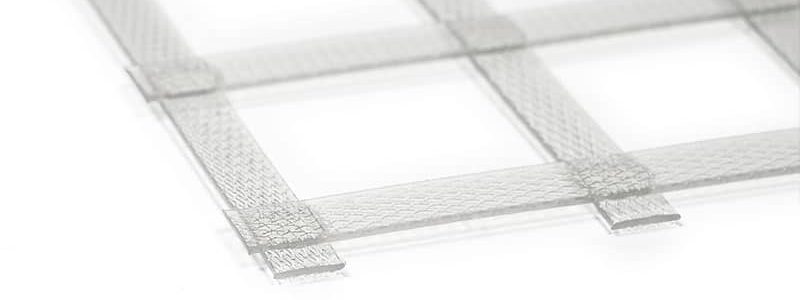

SECUGRID®

Secugrid® je strukturalno čvrsta i stabilna georešetka za ojačanje tla, izrađena od ekstrudiranih i rastegnutih polipropilenskih (PP) šipki koje su postavljene i čvrsto zavarene zajedno. Mobilizirani smični naponi u zrnastim tlima značajno se smanjuju kada se premaši relativno mala aksijalna deformacija (<2%). Georešetke smanjuju deformacije i povećavaju stabilnost, sigurnost i funkcionalnost zemljanih struktura. Ponašanje georešetke pod opterećenjem utječe na raspoloživu čvrstoću pri malim deformacijama; stoga, ojačanje smanjuje stvaranje kolotraga, ispupčenja, pukotina i druge mehanizme otkazivanja unutar cesta, kompozitnih struktura i drugih ojačanih slojeva tla. Secugrid® georešetke postižu visok modul elastičnosti i veliku vlačnu čvrstoću pri malim deformacijama te pokazuju malu sklonost puzanju. To je ključno za siguran, ekonomičan i dugotrajan inženjerski rad te visoku funkcionalnost.

- Stabilizacija i ojačanje temeljnog sloja

- Potporni zidovi i padine

- Upornjaci mostova

- Ojačanje obloga

- Bazalno ojačanje za nasipe

- Platforme za prijenos opterećenja preko pilota (LTP)

- Premošćivanje rudarskih šupljina i vrtača

- Ojačani temelji

- Zračne piste i nivelirani dijelovi

- Radne platforme, podloge za dizalice

- Rovovi za cijevi

- Visoka vlačna čvrstoća

- Snažna torzijska krutost

- Niska sklonost puzanju

- Robustan protiv oštećenja prilikom ugradnje, kemijskih i bioloških utjecaja

- Visoka dugotrajna čvrstoća

COMBIGRID®

COMBIGRID®

je kompozitni proizvod sastavljen od Secugrid® georešetke, s iglom probušenim netkanim geotekstilom Secutex®, čvrsto zavarenim između šipki za ojačanje, namijenjen primjenama stabilizacije tla, separacije i filtracije.

COMBIGRID® JE MULTIFUNKCIONALAN

Combigrid® objedinjuje sve potrebne karakteristike različitih svojstava u jednom proizvodu. Zbog toga je glavna primjena Combigrid®-a na slabim podlogama gdje su, uz ojačanje, potrebna i filtracijska i separacijska svojstva. To se uglavnom odnosi na podloge s CBR vrijednošću manjom od 3%. Stoga su područja primjene Combigrid®-a ojačanje temeljnog sloja, temelja, pristupnih cesta, rovova za cjevovode i u cijelom sektoru cestogradnje. Dostupna ponuda proizvoda obuhvaća različite stupnjeve vlačne čvrstoće i komponente netkanih materijala te pokriva širok raspon primjena. Combigrid® je, dakle, svestran proizvod za univerzalne primjene.

- Visoka vlačna čvrstoća

- Snažna torzijska krutost

- Niska sklonost puzanju

- Robustan protiv oštećenja prilikom ugradnje, kemijskih i bioloških utjecaja

- Visoka dugotrajna čvrstoća

SECUDRAIN®

SECUDRAIN®

je trodimenzionalni kompozitni proizvod, sastavljen od drenažne jezgre i čvrsto pričvršćenih filtracijskih netkanih geotekstila za drenažne primjene.

SECUDRAIN® JE MULTIFUNKCIONALAN

Secudrain® se široko koristi za odvodnju vode ili plina u raznim primjenama. U inženjerskim radovima na odlagalištima, Secudrain® istovremeno obavlja tri funkcije (filtraciju, zaštitu i drenažu) kada se postavi izravno iznad geomembrane. Njegova sposobnost pasivnog rasterećenja vodenog tlaka čini ga idealnim za drenažu iznad ukopanih struktura i u aplikacijama drenaže uz rubove cesta. Filtracijski geotekstili i drenažna jezgra mogu se učinkovito dimenzionirati kako bi zadovoljili potrebni kapacitet odvodnje. Secudrain® se također uspješno koristi kao drenažni sloj u izgradnji zgrada, tunela i krovova.

- filtracija, zaštita i drenaža u jednom proizvodu

- izvrsna protočnost unutar ravnine

- dugoročna hidraulička učinkovitost

- zamjenjuje prirodni drenažni agregat

- vrlo visoka otpornost na puzanje

- otpornost na kemijsku i biološku degradaciju

- savršeno prikladan za primjenu na strmim padinama zbog vrlo dobrih smičnih svojstava

- robustan u terenskim uvjetima

- brza i isplativa instalacija

- najviši standardi kontrole kvalitete

- ISO 9001 certificirano

- CE označeno

SECUMAT®

SECUMAT®

je trodimenzionalna prostirka za kontrolu erozije s labirintnom sintetičkom jezgrom.

SECUMAT® JE MULTIFUNKCIONALAN

Prostirke za kontrolu erozije Secumat® koriste se za zaštitu padina i tla u cestogradnji, krajobraznom uređenju te u radovima na odlagalištima. U hidrotehničkim radovima, Secumat® se primjenjuje na poplavnim ravnicama i nasipima. Pravilno dimenzioniran, sprječava klizanje i ispiranje tla i pokrovnog sloja, dok omogućuje brzi rast vegetacije. Tijekom obilnih kiša i vodenih tokova, ojačavajuća sposobnost Secumat® prostirke sprječava eroziju inače osjetljive vegetacije. Nakon što je vegetacija razvijena, Secumat® smanjuje brzinu otjecanja, povećava infiltraciju i smanjuje otjecanje vode. Uz vodene tokove, Secumat® štiti obale od erozivnog djelovanja vodenih struja.