Geosynthetics

The company GT Trade doo has specific experience and a professional approach in selecting materials for all applications. Our use of modern technologies complies with the requirements of EU standards. We are committed to continuous improvement, as well as to the prevention of environmental pollution. We shape the environment in which we live in order to use landscapes as efficiently as possible, without negative consequences. With our solutions and materials that we incorporate into various applications, we do everything to meet these requirements.

The company is actively involved in environmental protection through the rehabilitation of landfills, water protection, water protection in road construction and the construction of railway corridors and lagoons. Safe disposal of waste is the goal of every community, as well as one of the prerequisites for sustainable development. Uncontrolled waste disposal increases the risk of soil and water pollution. The use of geosynthetic materials, which facilitate construction thanks to their efficiency and simplicity, helps us protect the environment and its resources, and at the same time makes waste disposal safer.

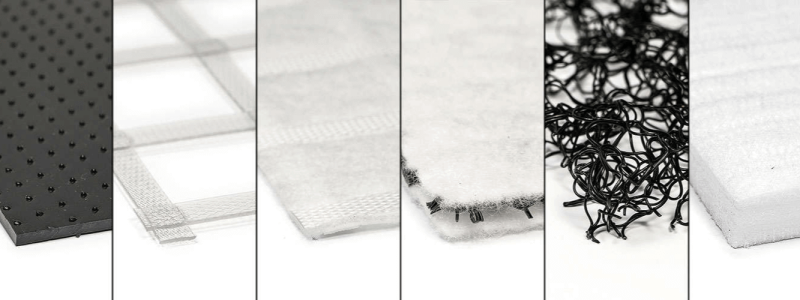

At landfills, HDPE geomembranes with a thickness greater than or equal to 2.0 mm are used almost exclusively. In groundwater protection, HDPE geomembranes with a thickness of 1.0 mm are mainly used. In applications in tunnels, geomembranes with a signal layer are most often installed. Steeper slopes can be adjusted by installing geomembranes with structured surfaces. Needle-punched geosynthetic clay sealing liners with mechanically bonded nonwovens (300 g/m2) as cover and load-bearing geotextiles are particularly suitable for steeper slopes because they typically achieve higher interface friction angles compared to other geotextiles.

Sealing is necessary for the protection of the environment and groundwater and significantly contributes to the usability and service life of buildings. Geomembranes of different thicknesses, depending on the purpose, are used as barriers for liquids and gases, mainly in landfills, in tunnel construction and in hydraulic engineering. Geomembranes produced from different formulations of polyethylene (eg different densities) are usually used. Thicknesses are generally greater than 1.0 mm. Geomembranes are installed and welded by authorized installers. In areas with lower loads, plastic sheets with a thickness of 0.3 mm to 1.0 mm can be used, which is applicable for temporary covers and, for example, for pond applications. Geosynthetic clay sealing liners are used in specific areas, with bentonite performing the sealing function.

Products:

In order to enable the long-term drainage functionality of the percolation layer, filtration geotextiles are used to transfer shear stresses to the percolation layer. Mechanically bonded nonwovens (see filtration) are particularly suitable for filtration functions. Randomly interlaced mesh matrices are particularly suitable as drainage layers because they have a stable three-dimensional static structure. Shear stresses can be transferred without damage, thus maintaining long-term hydraulic efficiency.

Drainage includes the collection of precipitation, groundwater, and other liquids or gases that must be drained. Drainage systems are supplied as individual elements or composites consisting of at least one filtration layer and one percolation layer. The percolation layer takes the liquid and drains it away with minimal pressure loss. Surface drainage systems are often combined with sealing systems, for example in landfills, and in waterproofing applications, such as underground car parks or tunnels. Geosynthetic drainage systems replace expensive mineral drainage layers.

Product:

Mechanically bonded nonwovens are particularly suitable for this function because they adapt very well to irregular substrates as well as soft soils, thanks to their high elongation capacity. This ability to elongate is important to accommodate stone penetration. The fibers wrap around the stone and prevent damage to the structure of the non-woven material.

Geotextiles separate adjacent soil types or bulk materials, preventing them from mixing with each other. They are used in the form of durable, robust non-woven or woven fabrics and/or composites produced from synthetic raw materials that can withstand high loads. Common applications include road and railway construction, hydro engineering projects and the construction of equestrian and sports fields. The selection of the appropriate product depends on the grain size distribution of the base layer material and the expected operating loads.

Product:

Thick mechanically bonded non-woven materials have proven to be very good protective layers. For example, Secutex® PP non-woven materials with a weight per unit area greater than 800 g/m² are used as the only protective layer for geomembranes. However, in areas of application where lower loads occur, mechanically bonded non-woven materials with a mass per unit area greater than or equal to 300 g/m² are used.

Geomembranes, coated and uncoated structures must be protected from mechanical damage. Without protective layers, there would be damage caused by sharp irregularities of the substrate or filling material. Non-woven materials and composites are used as protection against mechanical damage. Composites include nonwovens reinforced with woven materials, double-sided woven materials, and composite nonwovens with mineral fillers. The effectiveness of the protection depends on the thickness of the geosynthetics, their mass per unit area, as well as the resistance to perforations caused by impacts or compression. Nonwovens and composites are used in a variety of applications, including landfills and tunnels, to protect geomembranes. Such protective elements have also been successfully installed in the construction of pipelines.

Product:

Mainly, geogrids and woven materials are used as reinforcement elements. Reinforcement elements, where the reinforced parts are made from strands of cut films (eg woven materials), are more susceptible to damage during installation than reinforcement elements made from polymer ribs with solid intersection points. In addition, stretched geogrids have smaller initial elongations compared to woven materials, for example, and therefore immediately transfer forces without elongation during construction.

When used for reinforcement purposes, geotextiles, geogrids and composites are placed under or between soil layers to absorb tensile forces and thereby improve mechanical properties. Preference is given to their use in a supporting structure based on the principle of “reinforced soil” or for stabilizing earth embankments on soils with poor bearing capacity. In many cases, this makes expensive structural measures, soil replacement or the installation of an additional soil layer unnecessary.

Products:

Mechanically bonded nonwovens are particularly suitable for this function if the thickness of the nonwoven is at least 30 times greater than the selected opening size. This has been established by inspections of mechanically bonded nonwovens that have been in use for relatively long periods. The thickness adapted to the size of the opening enables deep filtration and prevents the formation of a filter cake at the interface between the geotextile and the soil, which would reduce water permeability. This ensures long-term water permeability of mechanically connected non-woven materials adapted to the soil.

The geotextile filtration layer retains solid particles, while allowing liquids to pass almost freely perpendicular to the filtration plane. A distinction is made between the mechanical strength (holding capacity of soil particles) and the hydraulic efficiency of the filter, with the aim of achieving water drainage with minimal pressure loss.

The requirements can also be met with a mineral filter, but geotextile filter layers have proven to be the most suitable and economical alternative.

As with mineral filter layers, the thickness of geotextile filters can affect the long-term mechanical and hydraulic efficiency of the filter. Filters are mainly used in hydrotechnical and drainage systems.

Products:

- Secutex®

- Terrafix®

Because of their very good flexibility, mechanically bonded nonwovens are particularly suitable as they enable robust handling thanks to optimal stress/stretch behavior and adapt well to substrates. In addition, the flexible system optimally deforms during the impact of waves, absorbing impact forces. Three-dimensional needle punched nonwovens are also particularly resistant to abrasion.

In geotechnology and hydrotechnics, earth materials are specially “packaged” in flexible pipes, bags and containers. Here, geosynthetics perform the functions of separation, filtration, protection and/or reinforcement, depending on the type of application. Materials used include non-woven fabrics, woven materials, geogrids and composites.

Product:

- Soft Rock® (Terrafix®)

Erosion of slopes can be very effectively prevented by the use of interlocking mesh structures, especially during the vegetation phase, because the soil filled in the three-dimensional static structure of the random interlocking mesh is securely held in place and becomes relatively resistant to washing.

Three-dimensional geosynthetics and composites prevent the removal of soil particles due to the action of water and wind. In nature, plants prevent soil erosion with their roots. The natural process of forming layers of vegetation, which often takes years, can be accelerated and enhanced by the use of erosion control mats.

Product:

The company GT Trade doo is the general representative of the German company NAUE GmbH & Co. KG for the area of Croatia and Bosnia and Herzegovina. In the past 40 years, the company NAUE GmbH & Co. KG has expanded its range of products and the area of their application, thereby ensuring its presence on the most important world markets. Today, on the territory of Croatia and Bosnia and Herzegovina, we offer the products of this company, along with conceptual and technical solutions for construction sites, including all geostatic and geotechnical calculations.

GT Trade doo manages the supply chain from material selection and procurement to international logistics, delivery and installation. We are one of the largest importers of geosynthetic materials in Croatia.

We have high-quality materials that have been tested by accredited professional organizations for certification and quality control, as well as proven solutions based on experience and comprehensive technical support for all phases of the project – from the proposal to the delivery of materials and installation.

We create main and executive projects in cooperation with our project office (BBG/ BAUBERATUNG GEOKUNSTSTOFFE).

BENTOFIX®

BENTOFIX® sealing barrier

Needle punched reinforced geosynthetic clay liner (GCL) with two geotextile layers encapsulating a layer of sodium bentonite for sealing applications.

BENTOFIX® X multi-component sealing barrier

Needle-punched GCL, where a woven fabric is coated with a low-permeability, gas-impermeable polyolefin coating to achieve an instant barrier before hydration.

Bentofix® is multifunctional

Bentofix® is an extremely versatile clay-based product. After hydration, Bentofix® becomes an effective barrier against liquids, steam and gases. With more than two decades of successful installations, the range of Bentofix® applications is practically unlimited.

- cover layers for waste and contaminated soil

- underlying membranes for landfills

- gas and vapor seals

- surface coverings of reservoirs

- secondary protection

- dams, canals and water courses

- tailings containment

- groundwater protection

- absorbent barriers

- vertical barriers

- waterproofing

- diverse sealing applications with different types of GCL and sodium bentonite

- can reduce construction costs by replacing compacted clay

- robust geotextiles encapsulate and contain bentonite

- withstands differential settlement

- uniform peel strength provides multidirectional shear strength

- The Thermal Lock process increases internal shear strength and friction angles at the interface

- self-sealing flaps available

- advantages of installation with 5 m wide rolls

- quick and easy installation

- BBA certified waterproofing systems (Bentofix® BFG 5000 and X2 BFG 5300)

- ISO 9001 certified

- CE marked

SECUTEX®

SECUTEX®

is a needle-punched non-woven geotextile made of connecting fibers, and some products are additionally calendered, used for separation, filtration, protection and drainage.

SECUTEX® IS MULTIFUNCTIONAL

Secutex® geotextiles are used in many areas of civil engineering, including hydraulic engineering, landfill engineering, road construction and tunnel construction. As a separation layer, Secutex® prevents contamination between individual and different granular layers. This keeps structural embankments and base layers intact for significantly longer than would otherwise be possible. When fine soil layers are present alongside drainage layers on highway or railway construction projects, Secutex® acts as a filter, preventing fine soil particles from being washed out and compromising the drainage capabilities of the coarser layers. The moving layer of water in problem areas is facilitated by the plane permeability of Secutex®. Secutex® nonwoven geotextiles with a high mass per unit area can also protect geomembranes or pipes from mechanical damage. If necessary, a woven geotextile can be integrated into the Secutex® matrix to distribute dynamic loads, thereby increasing its protective capacity.

TERRAFIX®

TERRAFIX®

is a single or multi-layer needle punched nonwoven material for separation, filtration, protection and sand tank applications.

TERRAFIX® IS MULTIFUNCTIONAL

Terrafix® is a versatile material used for a wide range of functions, including single or multi-layer geotextile filters, sand ballast mats, sand tanks or pipes, and erosion protection. Terrafix® non-woven materials and mats act as separators and filters in hydrotechnical applications, such as embankment construction, canal bed rehabilitation and protection, and coastal works. Terrafix® pipes made of this material are used to protect pools in ports; Terrafix® sand containers have been successfully used to protect coasts and riverbeds. Terrafix® has high water permeability, retains soil and allows roots to grow, so that coastal protection structures blend in seamlessly with the natural environment. Terrafix® provides erosion protection for linings, in waterways, around pillars and longitudinal and transverse hydrotechnical structures.

CARBOFOL®

Carbofol® HDPE geomembranes are produced from high-quality polyethylene resins. Carbofol® is produced in different thicknesses and up to a width of 7.50 m. For sealing applications on slopes, Carbofol® is produced with a relief structure.

- Covering layers and base sealing of the landfill

- Canals, ponds and reservoirs

- Tunnels and buildings

- Mining

- Storage, filling, handling, production, treatment and use of contaminated liquids

- Excellent chemical resistance thanks to selected raw materials

- High friction angles at the interface thanks to the embossed structured surface

- Advantages of installation with coverings up to 7.50 m wide

- A high Melt Flow Index (MFI) enables excellent welding performance

- Available in accordance with the GM-13 standard and with BAM and DIBt approval

SECUGRID®

Secugrid® is a structurally sound and stable geogrid for soil reinforcement, made from extruded and stretched polypropylene (PP) rods that are placed and tightly welded together. The mobilized shear stresses in granular soils decrease significantly when the relatively small axial strain is exceeded (< 2%). Geogrids reduce deformations and increase the stability, safety and functionality of earthen structures. The behavior of the geogrid under load affects the available strength at small deformations; therefore, reinforcement reduces the formation of rutting, bulging, cracking, and other failure mechanisms within roads, composite structures, and other reinforced soil layers. Secugrid® geogrids achieve a high modulus of elasticity and high tensile strength at low deformations and show little tendency to creep. This is essential for safe, economical and long-lasting engineering work and high functionality.

- Stabilization and strengthening of the base layer

- Retaining walls and slopes

- Bridge abutments

- Reinforcement of linings

- Basal reinforcement for embankments

- Platforms for load transfer over piles (LTP)

- Bridging of mining cavities and sinkholes

- Reinforced foundations

- Airstrips and graded sections

- Working platforms, platforms for cranes

- Pipe trenches

- High tensile strength

- Strong torsional stiffness

- Low tendency to creep

- Robust against damage during installation, chemical and biological influences

- High long-term strength

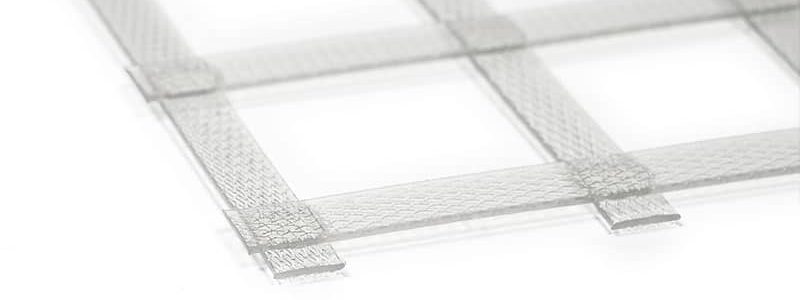

COMBIGRID®

COMBIGRID®

is a composite product composed of Secugrid® geogrid, with needle punched Secutex® non-woven geotextile, tightly welded between reinforcing bars, intended for soil stabilization, separation and filtration applications.

COMBIGRID® IS MULTIFUNCTIONAL

Combigrid® combines all the necessary characteristics of different properties in one product. For this reason, the main application of Combigrid® is on weak substrates where, in addition to reinforcement, filtration and separation properties are also required. This mainly applies to substrates with a CBR value of less than 3%. Therefore, the areas of application of Combigrid® are the reinforcement of the base layer, foundations, access roads, trenches for pipelines and in the entire road construction sector. The available product range includes different degrees of tensile strength and components of nonwoven materials and covers a wide range of applications. Combigrid® is therefore a versatile product for universal applications.

- High tensile strength

- Strong torsional stiffness

- Low tendency to creep

- Robust against damage during installation, chemical and biological influences

- High long-term strength

SECUDRAIN®

SECUDRAIN®

is a three-dimensional composite product, composed of a drainage core and firmly attached filtration non-woven geotextiles for drainage applications.

SECUDRAIN® IS MULTIFUNCTIONAL

Secudrain® is widely used for water or gas drainage in a variety of applications. In landfill engineering, Secudrain® simultaneously performs three functions (filtration, protection and drainage) when placed directly above the geomembrane. Its ability to passively relieve water pressure makes it ideal for drainage above buried structures and in roadside drainage applications. Filtration geotextiles and drainage core can be effectively dimensioned to meet the required drainage capacity. Secudrain® is also successfully used as a drainage layer in the construction of buildings, tunnels and roofs.

- filtration, protection and drainage in one product

- excellent fluidity within the plane

- long-term hydraulic efficiency

- replaces the natural drainage aggregate

- very high creep resistance

- resistance to chemical and biological degradation

- perfectly suitable for application on steep slopes due to very good shear properties

- robust in field conditions

- fast and cost-effective installation

- the highest standards of quality control

- ISO 9001 certified

- CE marked

SECUMAT®

SECUMAT®

is a three-dimensional erosion control mat with a labyrinthine synthetic core.

SECUMAT® IS MULTIFUNCTIONAL

Secumat® erosion control mats are used to protect slopes and soil in road construction, landscaping, and landfill operations. In hydrotechnical works, Secumat® is applied on flood plains and embankments. Properly dimensioned, it prevents slipping and washing away of the soil and cover layer, while enabling the rapid growth of vegetation. During heavy rains and water flows, the reinforcing ability of the Secumat® mat prevents the erosion of otherwise sensitive vegetation. Once vegetation has developed, Secumat® reduces runoff velocity, increases infiltration and reduces water runoff. Along with water courses, Secumat® protects banks from the erosive action of water currents.